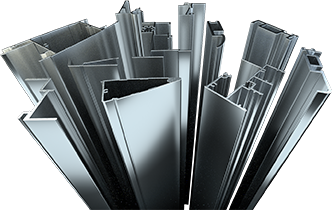

EXTRUSION

Astro Shapes’ broad extrusion capabilities provide our customers with cutting edge shapes and aerodynamic designs.

EXTRUSION CAPABILITIES

Astro Shapes’ commitment to quality includes maintaining its state-of-the-art equipment to handle the most demanding extrusion requirements. With our full range of 6 computerized extrusion presses, from 1400 ton to 2500 ton, Astro can produce the most intricate shapes for any market. By utilizing our capabilities and billets with diameters of 6, 7, and 8 inches, Astro can maintain level loading of production schedules to ensure that our customers’ delivery requirements are met.

• Alloys 6063, 6005A, 6061, and 6000 series equivalents available.

These alloys, when combined with T4, T5, T6, T61, and T52 tempers, ensure consistent physical properties along with the finest surface quality available in the industry.

Astro utilizes both Prime and Prime Equivalent billets to support LEEDS requirements. (For additional information on the LEEDS Program, please visit www.esgbc.org.)